3D Printing

"3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file."

Group Project - 3D Printing Tests

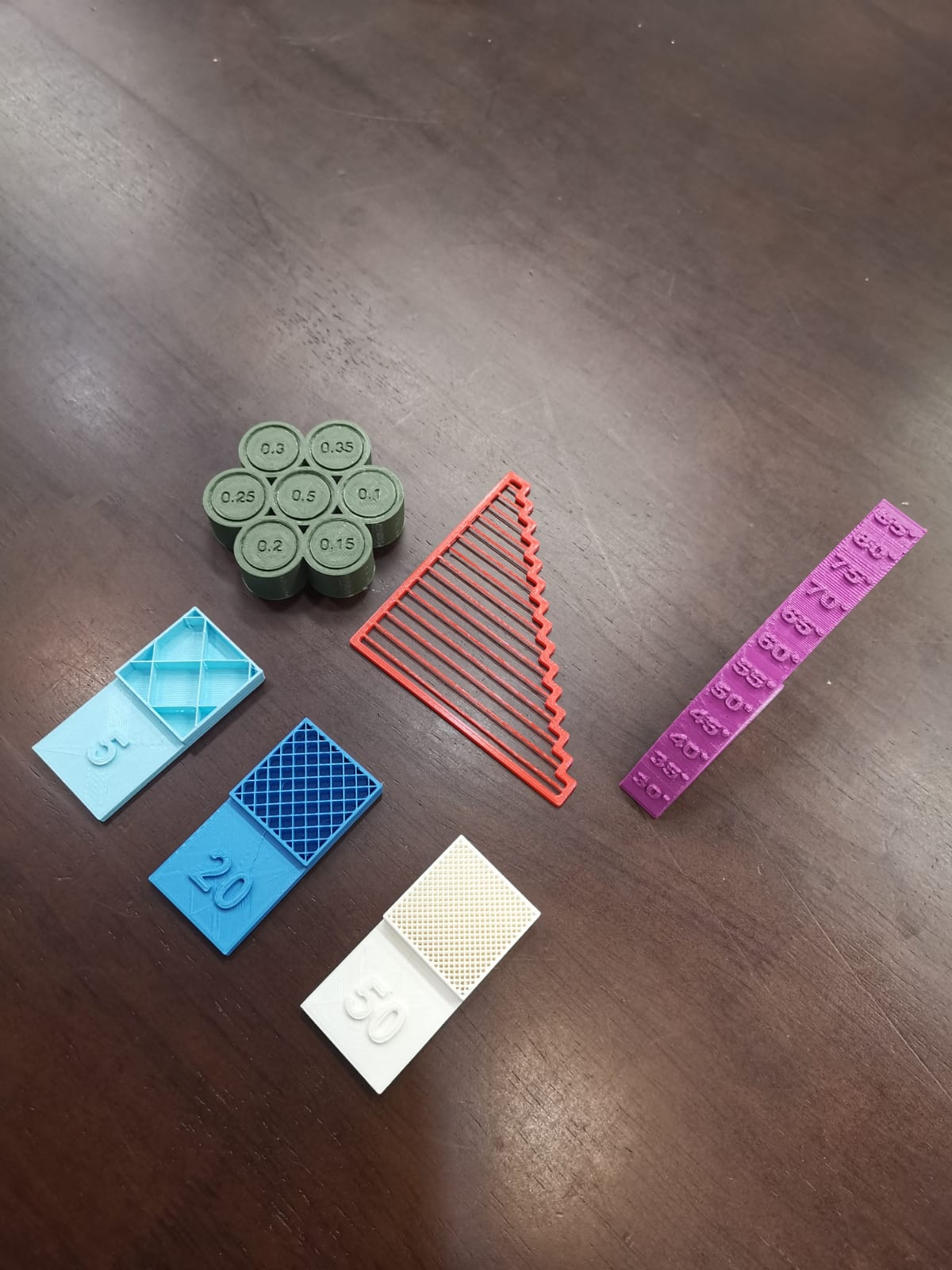

Our group was tasked to create 3D printed objects that test the limits of 3D printing including bridging, tolerance, overhang and infill density. I was given the role of designing a test for tolerance, and here was my final product:

The tolerance test worked! Some of the holes were able to spin freely while some of the other holes either took a great amount of effort to spin or did not move at all. The tolerances grew tighter the smaller the number went, from 0.5 being the most loose to 0.3 being the most rigid, while the rest of the numbers did not turn at all.

Right after the print, I noticed that all but the 0.5 tolerance rings did not move at all. I was very concerned because I had seen examples of the tolerance test working where most of the rings could move, so I tried to force twist the rings in order for them to move. After much agony, I could only get the 0.5, 0.35 and 0.3 to move about. I think that this is because of the settings that I used in Cura before 3D printing. Perhaps the print speed was too fast which would cause inaccuracies during 3D printing, thus the rings may have stuck onto the main base which causes the rings to be stuck. Thus, if I were to do this experiment again, I would set a lower print speed for the 3D printer to print more accurately.

Here is an image of all the tests put together:

Designing a Unique 3D Printed Object

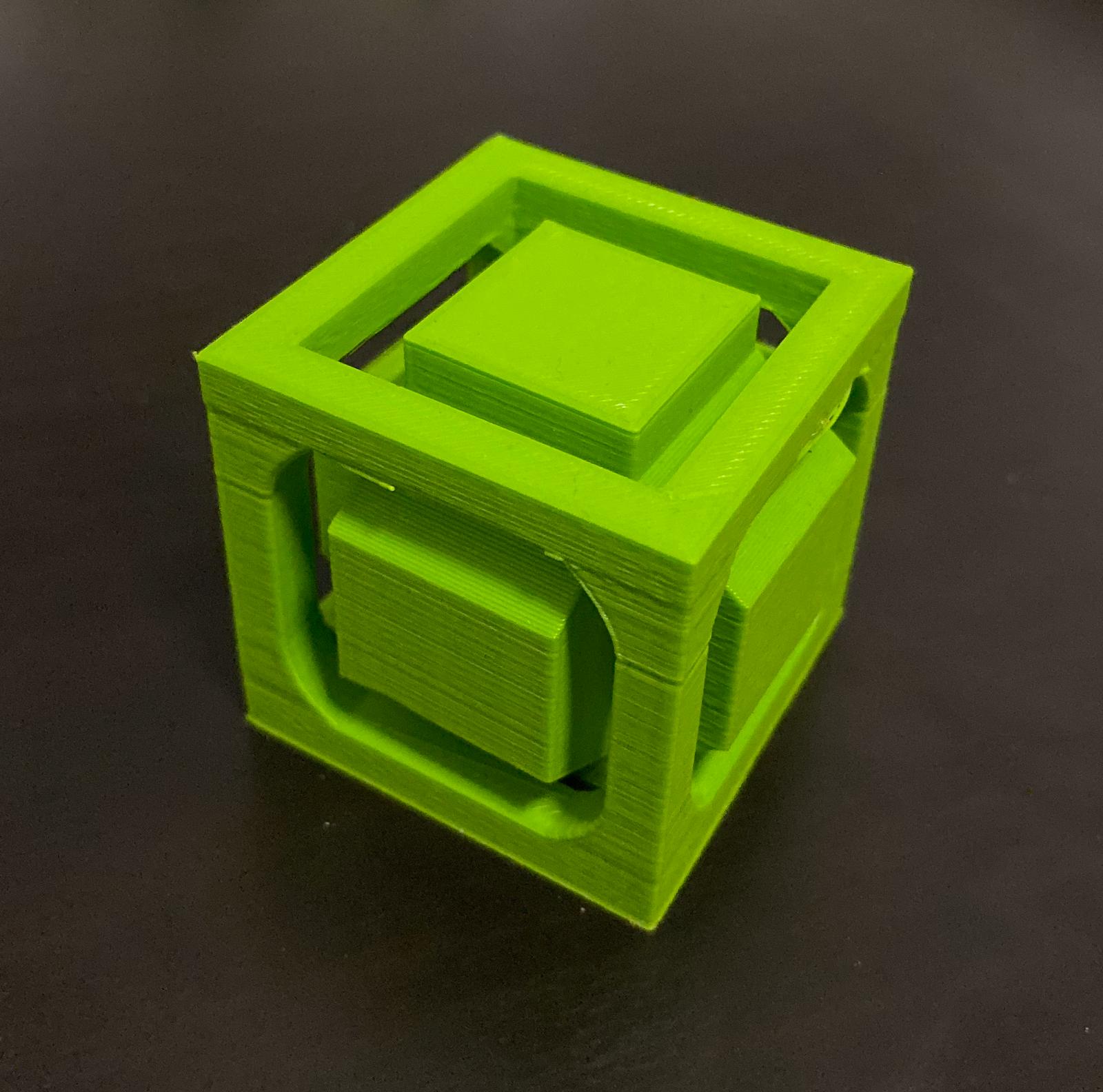

One of our assignments was to design a 3D printed object that could not be machined or CNC milled, meaning that the object design was exclusive to 3D printing only. Thus, I decided to 3D print an object inside another object at one go, where the inner object could not be removed. Here is a screenshot of the product in Fusion 360:

The object that I designed came out quite well out of the 3D printer. However, the overhangs of the object appeared very messy and frayed due to the size of the overhangs. In hindsight, I would have designed the object to be much smaller so that the overhangs would not be as big, which would lead to a cleaner print. Here is a photo of the printed object:

This is the file from the 3D printed assignment. [.f3d file]